Green

steam

ahead

As a Group, we are unleashing our strengths in an effort to drive fuel cell technology forward and help shape the future, the aim being to reach the pinnacle of ElringKlinger’s aspirations: to play our part in achieving carbon-neutral and climate-friendly mobility for society and the planet as a whole. The Group drives this success by innovatory prowess, creativity, and a measured approach to risk.

Serial product #1

NM5-EVO

The highly scalable and compact platform with 71 to 335 cells and a power rating of up to 76 kWel can be deployed, among other things, as a range extender for cars and light commercial vehicles in the automotive sector or for intralogistics applications such as forklift trucks.

Our company’s expertise is built on many years of experience in the development and research of fuel cell technology, representing a trump card that provides access to a wide range of hydrogen-based applications. Within the ElringKlinger Group, all of this expertise has been brought together at EKPO Fuel Cell Technologies GmbH (EKPO for short), a joint venture between ElringKlinger and the French supplier Plastic Omnium – based at the Group’s headquarters in Dettingen/Erms. EKPO develops and produces fuel cell systems and components for various applications. One of the company’s core products is the fuel cell stack. It is the “power plant” capable of generating energy by means of a chemical reaction, in our case of hydrogen and oxygen. At present, EKPO deploys systems that enable highly automated production to automotive standards of up to 10,000 stacks per year. What is more, its operations cover the entire process chain – from pre-assembly, stack assembly, and stack compression to final assembly and full end-of-line testing. Building on this set-up, the high-tech subsidiary can look forward to an exciting journey as it moves forward. To highlight our achievements and next-generation developments, we have selected three of the new orders placed with the company over the course of the 2023 financial year, the specific details and features of which are presented below.

The Classic

When it comes to complete fuel cell stacks, the emphasis is on individual compactness and high power density. For ElringKlinger, as an established development partner to automobile manufacturers, it is one of those “classic situations”: a carmaker places parallel development orders with the supplier, in this case EKPO, at an early stage. This means that our engineers and the customer’s engineers, as a supply-side team, work together as partners and in close cooperation during the development stage of the future vehicle. The fact that EKPO is awarded such contracts on so many occasions is also a testament to the outstanding performance features of its stacks: compact and customized stack design combining high power density and best-in-class quality. One of the orders for such stacks required a combination of a customized bipolar plate, which is a key component within the cell stack, and a matching high-performance MEA1 to achieve the specified performance targets. This is quite a challenge, especially when it comes to small installation footprints.

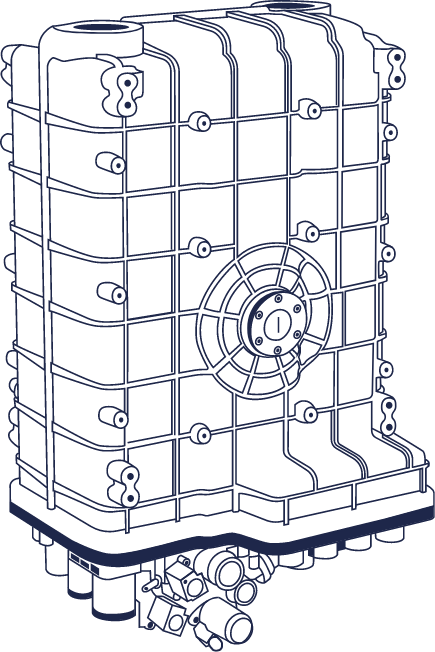

Serial product #2

NM12 Single

With its 359 cells and a power rating of 123 kWel, the NM12 Single stack is the perfect choice for a wide range of high-performance mobility applications.

The Ultrafine

The metallic bipolar plate – less than 1 mm thin and featuring ultrafine, micrometer-precise channel structures in extremely thin layers of sheet metal – has many parallels to a cylinder-head gasket in terms of process engineering. As regards complexity, both products appear to be relatively simple at first glance, but require high-precision punching, forming, and embossing. While the focus of the cylinder head gasket is on reliable and permanent sealing, the bipolar plate within the fuel cell stack has the task of supplying and distributing the hydrogen, atmospheric oxygen, and coolant. The gases react on catalytically active layers to form water and provide the electrical power.

Alongside R&D know-how, when it comes to the actual design, large-scale production also requires high-end industrialization expertise with regard to tooling, coating, treatment, and metal forming – based on an interlinked manufacturing process. Drawing on these core competencies, EKPO came out on top last year.

The spectrum of future applications for hydrogen-based, and thus climate-friendly, technologies is broad.

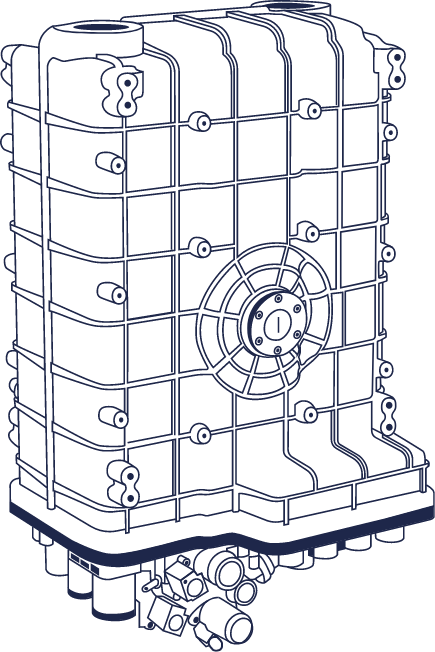

Serial product #3

NM12 Twin

The powerful Twin module has two sets of 299 cells and a power rating of 205 kWel. It excels above all in the heavy-duty, rail, and marine sectors.

The New

sive step forward for the Group in strategic terms. This is an apt description of EKPO’s entry into the promising electrolysis market. EKPO is currently developing next-generation components as part of a cooperation agreement concluded in 2023 with H-TEC SYSTEMS, a specialist in PEM2 electrolyzers and electrolysis stacks. PEM electrolysis exhibits better cold-start properties than so-called AEL electrolysis. The joint ambition is to establish a greenhouse-gas-free process for the production of green hydrogen. In contrast to the gray or blue hydrogen currently in use, this hydrogen is produced with the help of renewable forms of energy. This is used to power the electrolyzer, which splits water into hydrogen and oxygen. When it comes to establishing green hydrogen production and decarbonizing various industrial sectors in the future, the focus is on electrolysis stacks in the megawatt range. Speed was of the essence as part of this project, which is why EKPO, with its proven expertise in metallic bipolar plates and its existing infrastructure, is the perfect partner for large-scale production.

Green steam ahead

In its efforts to develop a new generation of stacks, EKPO is focusing on a solution for heavy-duty transportation. When compared to batteries, fuel cells are of particular interest to this sector due to their greater range, faster refueling options, and weight advantages. In 2023, EKPO received approval for federal and state funding of up to EUR 177 million as part of the European “IPCEI Hydrogen“ program, the aim being to develop a new generation of stacks for this high-performance segment of the market in particular. The funds also form an integral part of the German government’s national hydrogen strategy and will be allocated by the Federal Ministry for Digital and Transport and the Baden-Württemberg Ministry of the Environment in the years up to and including 2027. In addition, the company’s efforts in pursuit of its chosen path are underpinned by its involvement in various funding projects (e.g., HyFab, Ulm, BEST4Hy, EU, etc.) and the roll-out of activities at Group sites in North America and China. The spectrum of future applications for hydrogen-based, and thus climate-friendly, technologies is broad. This, too, forms part of ElringKlinger’s mission!